CAV vs. VAV: It’s Not Always So Clear Cut

Variable Air Volume (VAV) fume hoods save energy, right? No, not always. But yes, sometimes. There, that’s now clear as mud! The often maligned Constant Air Volume (CAV) fume hood has a legitimate place in many laboratories, and in certain circumstances it will not consume any more energy than a VAV fume hood would. Yes, you read that right.

Why Choose CAV Fume Hoods?

Why not use VAV fume hoods everywhere, “just in case” they can save energy? The advantages of using CAV fume hoods are many:

- Simpler airflow controls

- Less costly airflow control devices

- Easier to balance lab airflow and pressurization

- Reduced maintenance requirements

- Lower upfront cost compared to VAV systems

For the right applications, CAV fume hoods can deliver both CapEx and OpEx savings. (i.e. less maintenance and repair), but not in all circumstances. So, what is a lab design professional to do?

First, a Word of Caution on Cutting Costs

With the potential advantages of using CAV fume hoods in mind, let’s discuss when to consider using them. But first, we need to get this out of the way immediately: Yes, you can lower the total installed cost of a fume hood by using CAV models. However, we advise against this when the owner will be paying increased utility bills year after year, for the life of the lab, because of wasted energy by not using VAV fume hoods. Budgets have their limits, we understand that, let’s choose wisely where to cut costs but not sacrifice the client’s annual OpEx budget or sustainability.

When CAV Fume Hoods Make Sense

With that said, here are some of the more common situations where CAV fume hoods are the logical choice:

1. High Hazard Labs with High ACH Rates

For dilution of potential hazards, labs require differing amounts of Air Changes per Hour (ACH) of 100% outside air depending upon hazard levels. When the hazard is high, the lab room ACH rate is typically high also and there is a larger volume of air that will be supplied and exhausted from the lab regardless of any VAV or CAV fume hoods within it. This higher ACH rate can raise the number or size of CAV fume hood(s) that can be used prior to the total exhaust rate exceeding the high supply air rate.

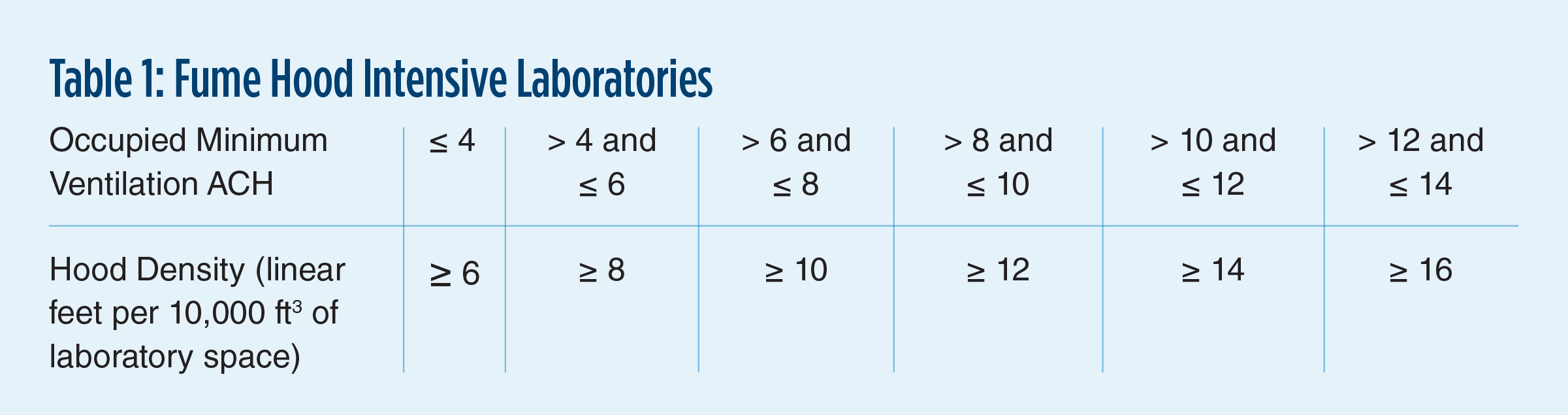

The rate of air exchange will be determined by an EH&S officer or other safety professional based on the hazards known to be or potentially present in the lab during normal work practices. Historically, “wet” chemistry labs have used occupied ACH rates in the range of 4 to 12 (during unoccupied times this may be reduced depending upon many factors). The mechanical engineers on the project can provide the resultant minimum ventilation rate of the lab and that can then be used to determine if CAV or VAV fume hoods should be used. As a good guideline, California’s Title 24 code contains a hood density vs. ACR rate chart for use with determining when to use sash closure systems. This chart is, thus, also quite helpful for determining when to use VAV fume hoods (i.e. fume hoods with sash closure systems must be VAV to save energy).

2. Using Lower Face Velocities with High-Performance Hoods

An energy savings trend of the last decade or more is using higher performance fume hoods which safely contain, dilute, and exhaust hazards at lower face velocities. Face velocity is the speed the room air enters the open sash area, typically measured in Feet per Minute (FPM). Lower face velocities mean that the total exhausted air is reduced, sometimes allowing more or larger CAV fume hoods to be used prior to exceeding the lab’s ACH rate. A face velocity of 60 FPM for a high performance fume hood is a reduction of 40% from the old industry rule of thumb of 100 FPM.

60 FPM = 40% less than traditional 100 FPM

Note: certain research is more hazardous and/or requires greater dilution and thus low face velocities should only be used when safe to do so with the research or instruction be performed within the fume hood. Point being, when considering lower face velocities, CAV fume hoods could potentially be used without sacrificing energy savings.

3. Low Flow Fume Hoods with Limited Sash Openings

Similar to low velocity fume hoods, low flow fume hoods may also be good candidates for CAV. Low flow fume hoods may have traditional face velocities (80 to 100 FPM), but they are designed for sash openings of only the agreed upon operating height (typically 18” instead of a full 28”). This reduces the maximum exhaust volume (thus low flow) from the fume hood and here again CAV may be applicable.

4. Large Labs with Few Fume Hoods

Almost regardless of the ACH rate, if the lab is fairly large and only has one or two fume hoods in it, this is an immediate indicator that CAV fume hood(s) should be considered. When you look at a lab and play what I like to call the “Where’s my hood at?” game, then you know you have a large lab and only one or two fume hoods. If these hoods were VAV, when they reduced the hood exhaust flow, a room exhaust valve would simply open in the same proportion – saving no exhaust air and thus offering no potential for energy savings.

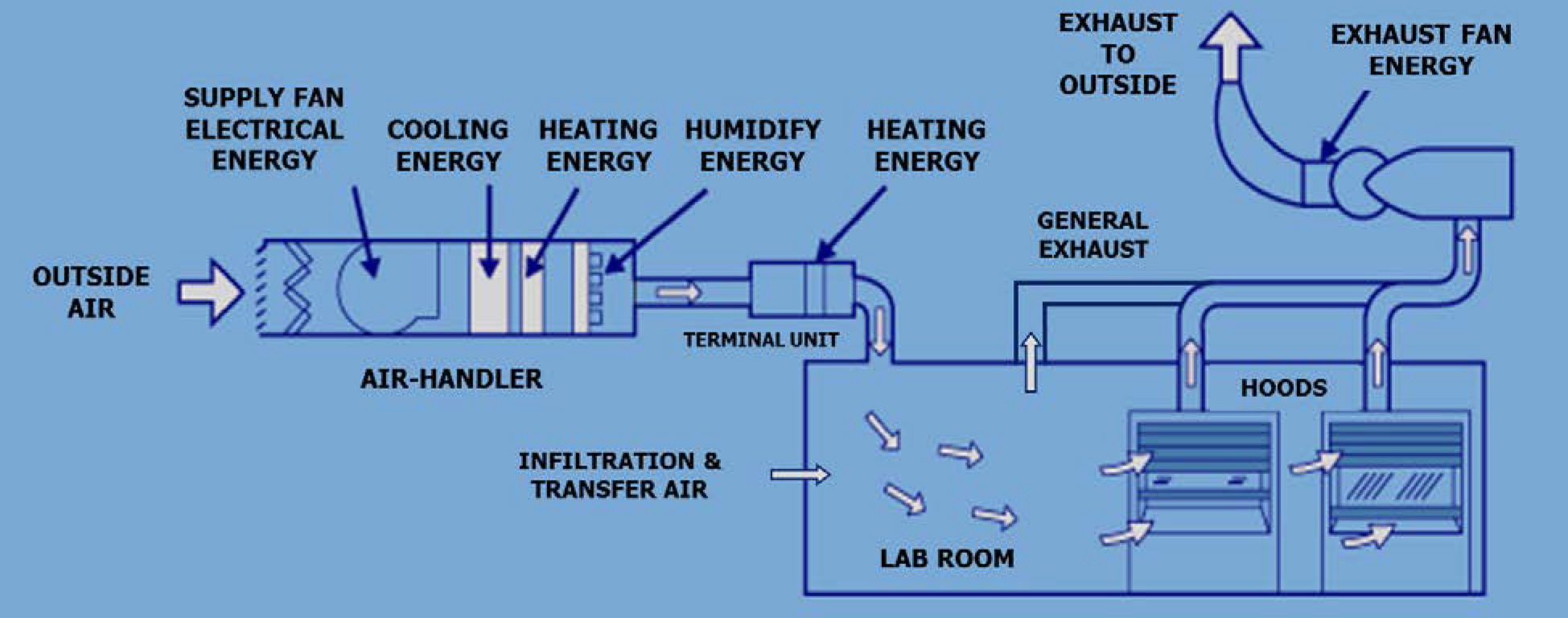

Note: the vast majority of energy savings will come from reducing the costly supply air (i.e. air that must be filtered, cooled, heated, humidified, dehumidified, and finally delivered to the lab).

5. Adding to Existing CAV Infrastructure

You are adding a fume hood to an existing lab that is already using all CAV fume hoods. In this case, unless you have the opportunity to upgrade the entire lab to VAV controls, it makes sense to stick with yet another CAV fume hood. But put this potential energy savings upgrade on your list of future projects.

CAV vs. VAV: Clear-Cut Application Examples

Applications that are, in the author’s opinion, painfully obvious candidates for either CAV or VAV fume hoods include:

CAV Fume Hood “No-Brainer” Applications:

- Biology labs are very low fume hood density labs and thus CAV fume hoods should be considered first.

- Large life science labs with many rows of work benches but just a fume hood or two, possibly off in an alcove, are primed for CAV fume hoods (remember: “Where’s my hood at?”).

- If a large amount of ductless fume hoods are being used, the few ducted fume hoods in the same lab will likely be candidates for CAV.

- Any lab with just one fume hood is a candidate for CAV (unless the lab is the size of a closet!).

- Specialty hoods and applications (e.g. Perchloric Acid, Radioisotope, Hydrofluoric Acid, etc.) are usually CAV for simplicity and safety.

- Any fume hood application that requires a high amount of dilution (e.g. Acid Digestion, High Heat/Exothermic Loads) will most likely be CAV but possibly VAV with a much higher minimum flow when the sash is closed (oh yes, there are degrees to the amount of VAV range – what, you wanted simple?).

VAV Fume Hood “No-Brainer” Applications:

- Chemistry teaching labs, especially organic and inorganic chemistry, are high fume hood density labs and therefore VAV fume hoods should be used in almost all cases.

- Pharma research labs with many bays of larger fume hoods should be VAV.

Important Considerations for Both VAV and CAV

There are many important points about both VAV and CAV fume hoods that should be mentioned in this discussion. Here are a few:

A. User Behavior Impacts VAV Effectiveness

VAV fume hoods can only save energy when their sashes are actually closed. Poor user practices (i.e. leaving the sash open) will undermine energy savings faster than children leaving bedroom lights on (!) and render the fume hood effectively CAV for the price of VAV. There are optional layers of automatic controls that can be added to either reduce the face velocity when users are not present, or to close the sash after users walk away. These controls add more cost, complexity, and maintenance. Effective user training programs to “Shut the Sash” may be more effective overall and can improve safety by having sashes closed more often. But only if the users participate.

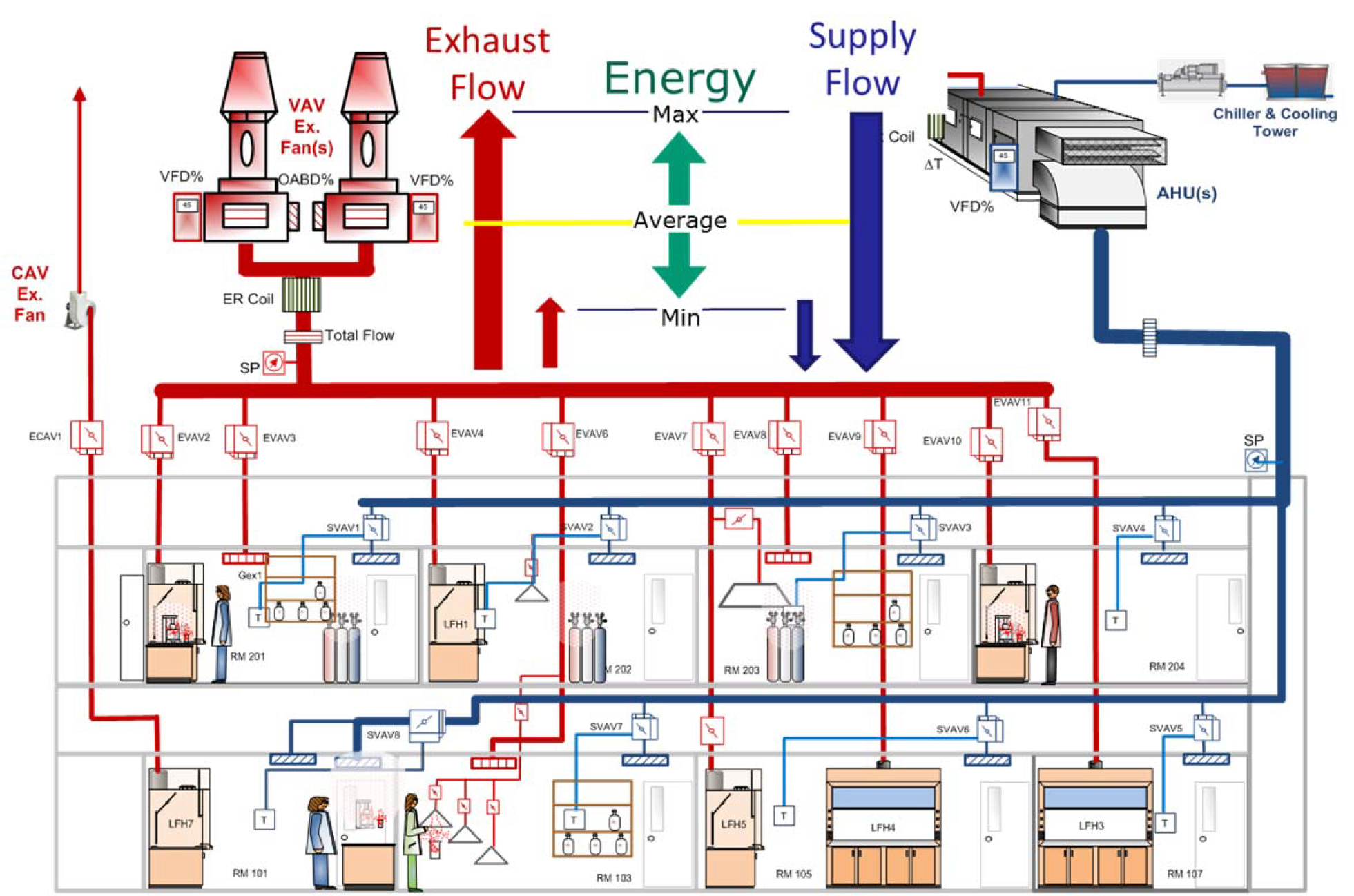

B. VAV Depends on System Integration

Even with the sash closed, VAV fume hoods can only save energy when all the other interconnected systems are installed, programmed, commissioned, maintained, and working correctly. This includes:

- The sash position or air velocity sensor on the fume hood (sometimes both!)

- Sash closure or occupancy detection system (if equipped)

- Variable position airflow control device connected to the hood exhaust duct

- The building automation system (BAS/BMS) that collects critical information for proper balance of the lab airflow

- Control of all the system-level devices such as exhaust fans, air handlers, chillers, boilers, energy recovery units, etc.

It’s rather complex and costly to operate laboratory ventilation and exhaust systems, just look at this diagram:

C. CAV = Constant Volume, Variable Face Velocity

CAV fume hoods are constant volume, but they are also variable face velocity. A “bypass area” is used to allow a portion of the exhaust air to leave the hood through other openings as the sash is closed. This bypass area is typically above the sash and is more exposed as the sash slides down, no longer blocking some or all of the bypass. Bypass helps regulate the face velocity and prevents it from increasing too much. Even so, the face velocity will not remain steady like it does with properly functioning VAV fume hoods. Instead, it is common to see the face velocity on a CAV fume hood increase by 2.5 times or more as the sash is fully closed. If this higher velocity with the sash closed will somehow disrupt the research being performed in the fume hood, then a VAV fume hood is likely the better solution, even if it doesn’t save energy.

In Summary

The decision to use VAV or CAV fume hoods can be complex and varies by application. “Safety First” applies in every situation, regardless of VAV or CAV. After that, take a moment and look closer, you may recognize some labs that are perfectly suited to CAV fume hoods, saving first costs and not consuming any more energy than a VAV fume hood!

References:

- US DOE, Better Buildings Alliance, 2014, A Guide to Navigating Building and Fire Codes for Laboratories, Enabling demand-based ventilation and optimized minimum air changes per hour

- California Energy Commission, 2019, Laboratory and Factory Exhaust Factsheet

- SEFA, 2019, Selection and Management of Exposure Control Devices in Laboratories

Want to explore whether CAV or VAV fume hoods are the right choice for your lab project?

Every lab is different — so is the best ventilation strategy. Connect with our experts to discuss your specific application and fume hood needs.

Contact Mott or your local Mott dealer today, and let’s talk about how we can help you build the right solution for your lab.